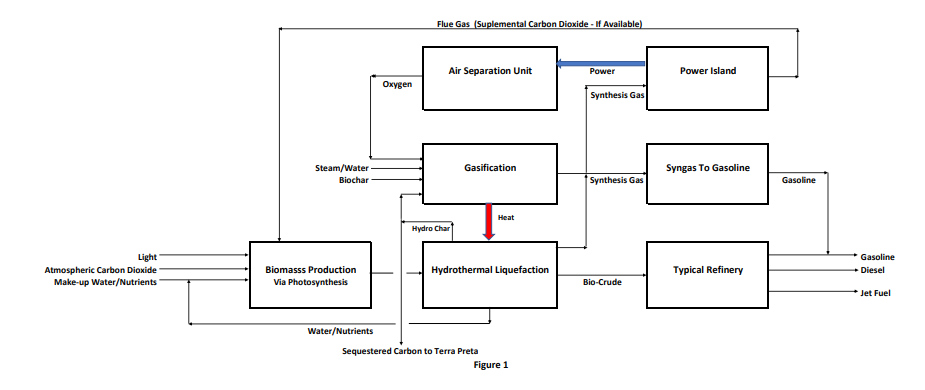

The Combination Process (see Figure 1 – click to enlarge) uses CO2 captured from the air and (if available) a nearby source of flue gas, combining the CO2 and water using light energy. The biomass product is formed via photosynthesis from cultivating Azolla and/or an algae. The biomass, preferably both algae and Azolla in combination, is processed to a crude bio-oil, and a carbonaceous residue, using the Hydrothermal Liquefaction process. The Hydrothermal Liquefaction process uses some of the waste heat in cooling the synthesis gas, following the gasification step. The carbonaceous residue from the Hydrothermal Liquefaction step results in “Hydro Char”. The hydro char can either be sequestered as a soil amendment or could be fed to the gasifier, along with biochar (if available) for partial oxidation to produce additional renewable synthesis gas. The crude bio-oil is processed in a conventional refinery to produce renewable refinery fuels. The cooled synthesis gas is further treated and used to produce renewable commodities, including renewable transportation fuels using the conventional commercial process routes developed over decades.